CO-718 Series Cartridges for Fuel and Oil Treatment

The Velcon CO-718 Series elements are intended for use in all clay treatment vessels designed for nominal 7” x 18” cartridges. The treatment/purification medium is a special blend of low volatile materials (LVM) fuller’s earth compounded to provide the optimum balance between adsorptive capacity and water resistance. With their ability to prevent channeling and their high particle structure stability, the elements assure reliable performance and long life in the most exacting process applications.

For further information on clay and how to deterrmine when the clay elements should be changed see data sheets.

Specifications

Series |

N/A CO-718 |

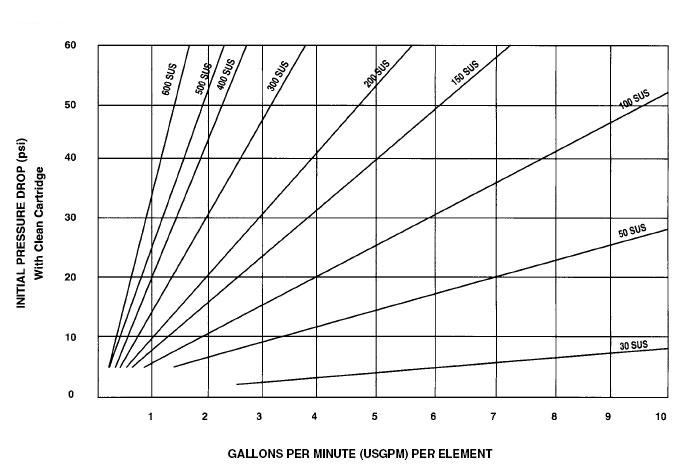

Pressures |

N/A 100 psi |

Flow Rate |

N/A 6.5 gpm |

Cartridges Size |

N/A 7 x 18 in |

Length |

N/A 18 in |

Outer Diameter |

N/A 7 in |

Center Diameter |

N/A 2 1/4 in |

Collapse Strength |

N/A 100 psi |

Interchange |

N/A Facet/Fram C-766-3 Keene-LE-718 |

Construction

|

N/A CO-718CE is a rugged canister element featuring aluminized steel endcaps and center-tube, polyester felt outerwrap and both interior and exterior media migration barriers. A wire bail provides for easy installation and removal. Buna-N gaskets at each end assure tight sealing. The improved construction offers high resistance to transit or handling damage and to differential pressures up to 100 psi. |

Jet Fuel Treatment

|

N/A One of the most common uses for clay elements is to remove surfactants from jet fuels. Surfactants can carry over from the refinery process or be picked up when the jet fuel travels through multi-product pipelines (corrosion inhibitors, gasoline additives, etc.). Surfactants will eventually disarm filter/separators, which are primarily designed to remove water from the jet fuel. By removing surfactants from the fuel, the clay elements protect the downstream filter/separators. Since clay removes the surfactants by an adsorbent (adhering) action, the fuel residence time, or time in contact with the clay, is very important for proper fuel treatment. Normally, a flow rate of about 6.5 gpm per 7” x 18” element is ideal for jet fuel. |